Table Of Content

Members know that working together is the best way to strengthen not only the industry as a whole but also their own companies. Join SBCA today and gain access to all of the membership programs and tools right at your fingertips. This means a strong barrier that reduces overall noise, which otherwise travels through the floor. A popular variation of the Warren truss turns the W’s upside down to create a series of “M” shapes instead. Find a flooring specialist in your area, and get free, no-commitment estimates for your project.

Exact Fit. On Time. Every Time.

Furthermore, trusses are made using exceptionally quality lumber, which minimizes the risk of shrinkage, warping, and twisting, reducing maintenance costs. Moreover, they are easier to work with and provide a nailing surface of about 3.5”, greater than the 2.5” surface offered by most I-joists. For instance, a wooden truss can span up to 30 feet, which is much greater than a traditional joist. They also allow for the construction of longer spans, are reusable, and require less labor to install. Howe trusses are more popular than Pratt trusses because of their superior load-dissipating capabilities.

How to Reinforce Ceiling Joists to Handle Heavy Loads - Fine Homebuilding

How to Reinforce Ceiling Joists to Handle Heavy Loads.

Posted: Wed, 01 Sep 2021 15:22:45 GMT [source]

Solutions with Floor Trusses

Floor trusses and joists are an essential part of any construction project, and it’s helpful to know their advantages and disadvantages and the types available. Most people divide them into three categories, but here are five types of floor trusses and joists. Open Web Trusses are available in nine profiles so you can design and build almost anything. Whether your project has an incredibly long span or is a typical light commercial job, we have a solution. With a high strength-to-weight ratio, open web trusses are uniquely suited for large open spaces and easy installation of plumbing, electrical, and ductwork. We build each truss by hand specifically for your job, then ship it upright for strict quality assurance.

ELIMINATE WASTE AND IMPROVE CYCLE TIME WITH OPEN WEB FLOOR TRUSSES

It is also crucial to include any custom designs in trusses before transporting them to the site. Floor trusses can also have custom designs and strengths to suit the needs of a homeowner or a designer. It requires steel or metal with high compressive strength, making it suitable for long spans. Another advantage includes the design of the floor truss itself, which allows for insulation to be put into place, reducing both impact noise and overall sound. But it will also depend on the size, depth, width, length, and type of wood used. The triangles create a webbing effect that not only supports the floor the trusses also allow for the placement of cables, plumbing, and vents.

Best Whittling Knives of 2024 – Reviews & Top Picks for Wood Carving

A bottom chord can be multiple pieces of lumber secured by a metal plate known as a splice, either at a joint or mid panel. While a vast majority of trusses will have bottom chords of the same species and grade, changes in both lumber species and grade are possible at splice points. This is most often seen in attic trusses where the bottom chord is increased in the living space and additional loads are applied and then reduced near the bearings to reduce expense. Customized beam pockets can be designed into floor trusses to accept various materials inserted through the webs. Trusses can be designed to support load-bearing headers at openings or to carry other floor trusses.

84 Lumber opens new North Carolina truss plant - LBM Journal

84 Lumber opens new North Carolina truss plant.

Posted: Thu, 01 Jul 2021 07:00:00 GMT [source]

Keyed Bearing or Shared Bearing details allow two different floor trusses to share the same interior bearing and stay aligned, eliminating the need to stagger or overlap the two trusses. Sheathing installation is much easier because the supporting trusses line up, significantly reducing the need to cut special sheathing pieces to complete the subfloor. The result is a cleaner detail with full bearing while reducing labor and material usage. Floor trusses and joists are used to support weight and provide structural support.

What is a Floor Truss – Types, Benefits, & Usage

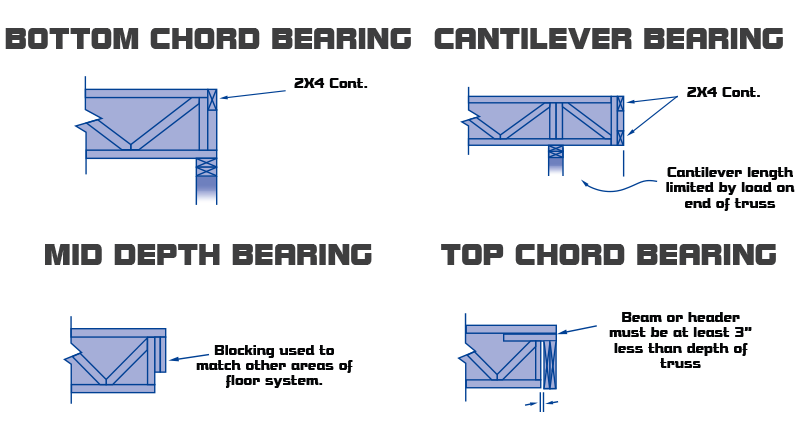

This is the most common type of chord-bearing condition in floor trusses and is designed to sit on top of bearing walls. Other trusses can also be used to support adjacent trusses connected at some type of angle, usually 90 degrees with a metal connector joist or truss hanger. In some instances with very light loads, trusses can be nailed together to act as a bearing condition. The bearing supporting the girder truss is most likely to suffer from the crushing effects mentioned above. I-joists have a top and bottom chord, like trusses, but the space is filled chiefly with ½” or 5/8’ plywood.

Solid Lumber Joists

Floor trusses are engineered with open web designs capable of spanning longer than traditional wooden I-joists. Various types of floor trusses are used in a floor system, including Warren, Pratt, and Howe trusses. Triangulation is the engineering practice of forming rigid triangles together with adequate fasteners at the joints. It typically involves the use of triangular shapes to give stability to structures. In roof and floor trusses, wooden triangles are used to pass compression and tension forces throughout the structure to its bearings.

Pratt Truss

Floor joists come in many sizes, but they usually range from 2 x 8’ to 2 x 12’. Sometimes, they can also be 2 x 6’, although these sizes are not very common and are mostly seen in older homes. The TrimJoist® can be quickly incorporated into any house plan and is the first step to a floor system with superior quality and superior support.

Before you purchase and decide which floor trusses and joists to choose, make sure you know everything about them. Consider the price, the location, and the durability before making your final choice. Solid lumber beams can be cheaper than engineered wood when it comes to the price, but the investment will not pay off in the long run. A good thing about solid lumber joists is that they are more fire-resistant than LVL Joists or I-Beams.

With floor trusses, you can simply run equipment through the webbing or provide horizontal chases in the trusses to provide the space needed. Wood is in fact a renewable resource, affordable, easy to work with, and provides enough strength for most projects. Wood products range from commodity lumber (2x4s, 2x6s, etc.), engineered lumber, (LVLs, Plywood, etc.), and pre-fab trusses. In today’s blog, we discuss floor trusses and what benefits they offer to both single-family homes and multi-family projects. These bearings need to be supported by an adequate support structure downward though the wall to any floor systems below and into the foundation system of the structure. Floor trusses are the solution to many floor framing challenges presented in today's complex and sophisticated building designs.

Wooden floor trusses are cheaper and easier to install but allow for smaller spans to be built. One of the most common support systems for floors in houses and commercial buildings is the open-web truss system. Their appearance makes them seem easy to build because they look as if they are just straight pieces of lumber with angled pieces between them. A preassembled unit of floor joists, subflooring, finished flooring, and sometimes ceiling below supported by walls, columns, or beams. Bearing width knowledge is critical to truss design to ensure the truss meets expectations in the construction process. If the bearing size varies from the truss design, the ceiling area can be impacted where it meets the wall and modifications will be necessary when installing drywall or other finish products.

Floor trusses offer greater strength and dissipate loads more efficiently than I -joists. However, the main disadvantage of using steel floor trusses is their high cost. SBCA invites and encourages individuals in the component manufacturing industry to join! The main reason structural building component manufacturers and those who supply them join SBCA is to learn from their peers. In typical trusses with an overhang, the top chord is extended past the bearing over the bottom chord to create an eave condition for the structure. Most top chords are cut with a plumb cut at the peak and overhang and a square cut at splices.

Ft. homes were built – one conventionally framed, the other built with engineered components – to highlight the benefits of building with roof trusses, floor trusses and wall panels. Floor trusses feature built-in ribbon notches that can be designed/customized to receive any dimension of 2x lumber desired. Continuous ribbons provide stability for installed trusses and a solid surface for the edge nailing of floor sheathing. This approach eliminates the need for larger and more expensive band-board solutions required by dimensional lumber and other engineered wood products.

Additionally, they have an open web design which allows easy access for utilities. Pratt trusses have a unique arrangement, and their diagonal members slant towards the middle. Michael Straessle has written professionally about the construction industry since 1988. He authored “What a Strange Little Man,” among other books, and his work has appeared in various online publications. Straessle earned a Bachelor of Arts from the University of Arkansas at Little Rock in professional/technical writing.

Panel points are located where web members intersect with top or bottom chords, which are connected by metal connector plates. Panel points determine the length of the panel and webbing formation of the truss. Shifting panel points even small distances can impact the efficiency of the truss and transform a truss that doesn’t pass design requirements to a truss that does. In floor truss applications, 2x4 or 2x3 material is typically used with the wider portion of the board resting on the bearing or what is known as a 4x2 configuration. Gable end floor trusses, sometimes called ladders, provide a strong alternative to large dimensional lumber for parallel closure.

No comments:

Post a Comment